Estimates suggest that nearly a third of the food produced for human consumption globally—roughly 1.3 billion tonnes a year—is wasted or lost on its journey from farm to table. At the same time, between 691 and 783 million people did not have sufficient access to food in 2022.

Reducing food loss and waste is not just essential for improving the sustainability of our food systems and supply chains while reducing the environmental impact of food production. It is also fundamental in a world where the number of people affected by hunger has slowly been rising since 2014 while tons and tons of edible food are lost or squandered each day.

The International Day of Awareness of Food Loss and Waste on 29 September is an opportunity to raise awareness for action to reduce food loss and waste toward food system transformation. Through our programme on Food Loss, Waste Reduction and Value Addition, NRI has been at the forefront of research and development efforts to avert food loss and waste and catalyse a sustainable global future.

From advances in drying and storage technologies to revolutionary food processing solutions, here are six of the ways NRI is helping to address food loss and waste across the world.

Advances in Pneumatic Drying

Cassava has a short shelf life and for human consumption needs to be processed into flour within 48 hours after harvest. The efficiency and speed of cassava processing plays a key role in minimising losses and ensuring food security. Pneumatic dryers (using compressed air for drying) are widely recognized as the most efficient method for drying granular materials. However, while large-scale industrial pneumatic dryers are readily available, smaller-scale options have been limited. Using Simulation-based Participatory Technology Development (SBPTD), we have designed a small-scale and a medium-scale pneumatic dryer, along with an advanced heat exchanger and two innovative feeders specifically designed for handling sticky materials like fresh cassava. These technologies not only improve drying efficiency but also decrease energy consumption by 30%, resulting in reduced emissions and a more sustainable process. This equipment has been adopted by several food processing companies in sub-Saharan Africa and is currently in operation in Ghana, Nigeria, Tanzania, and Uganda. SBPTD involves integration of all types of knowledge including indigenous and technical from all disciplines and domains as well as active stakeholder participation in technology design and development. This ensures that technologies are well suited and operate effectively within their specific contexts.

New machinery for cassava processing

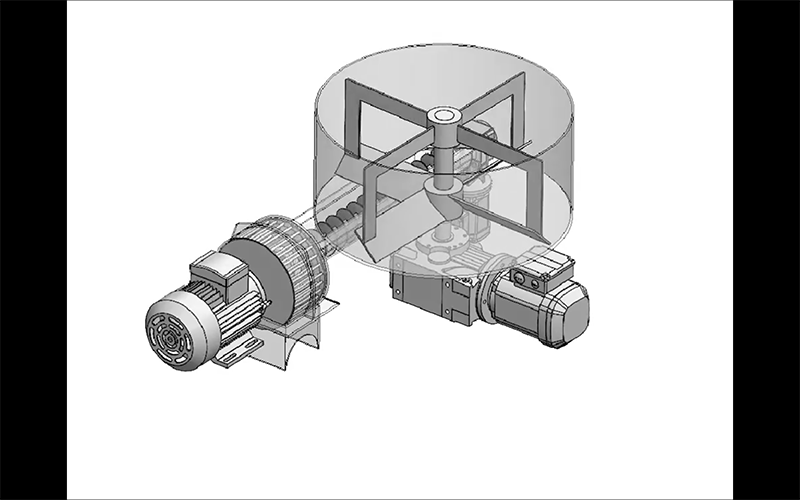

We have used Simulation-based Participatory Technology Development to design three novel cassava dewatering tools that employ pressure to reduce the moisture content of grated cassava pulp. These are a hand-winch-operated small-capacity press, a chain hoist-pred larger-capacity press, and a continuously operated press powered by an electric motor. These solutions reduce the manual labour requirement and address the inefficiencies and challenges of traditional dewatering techniques such as inconsistent moisture reduction. Additionally, our food loss and waste reduction team created a cost-effective instrument for measuring the force being applied by the instrument during pressing. They have also developed a solar-powered hammermill that can efficiently process both fresh cassava roots into mash and dried cassava grits into flour. Further, the NRI team designed a cassava peeling machine with rotating brushes to minimize waste and peel retention. Finally, all these technologies have been combined into a compact ‘factory-in-a-container’ solution, including a roll crusher, screw conveyors, roller press, pneumatic dryer, and hammer mill, capable of processing up to 13,200 kg of fresh cassava roots per day. These innovations have greatly impacted the cassava processing industry by boosting efficiency, improving product quality, and increasing profits.

Optimising storage, extending shelf-life

Once harvested, fresh fruit, vegetables and root crops are perishable and deteriorate at various rates, with storage lives ranging from days to months depending on the commodity. Optimisation of storage conditions can significantly impact on the loss and wastage of fresh produce. More efficient management of the crop can be achieved by extending storage times. Our Produce Quality Centre (PQC) provides high quality independent research for the fresh produce industry. With experts in storage of perishable produce and facilities to test and optimise storage conditions, the PQC is a leading centre for testing controlled atmosphere (CA) storage. CA storage is a process in which fresh produce is stored under narrowly defined environmental conditions of temperature, oxygen and carbon dioxide concentrations at high humidity to maintain quality and extend their useful postharvest life.

Our PQC has been central to several key initiatives supporting the fresh produce supply chain through adoption or optimisation of CA storage. Kent ‘Gala’ apples can now be stored almost year-round at very low oxygen concentrations (0.5 – 1%) following trials in which apples were monitored for stress by measuring respiratory characteristics. Not only has this reduced apple storage losses but has also led to a reduction in the quantity of apples imported into the UK from the Southern Hemisphere.

Our research has led to improvements in the storage environments maintained during sea-freight. This has enabled some commodities, previously air-freighted to the UK to be sea-freighted instead, with associated reductions in carbon emissions. For example, asparagus is now routinely sea-freighted to the UK from Peru.

The PQC has demonstrated that UK cherries can be stored successfully under controlled atmosphere under CA for six weeks, which could potentially double the length of the UK cherry season.

In-field cooling solutions

At the time of harvesting of fruits and vegetables it is essential to remove the field heat from the crops immediately to maintain good quality and reduce postharvest loss and waste in the supply chain. Research at the PQC, has demonstrated that rapid cooling of strawberries after harvest is essential for maintaining fruit quality for longer. Delaying cooling beyond the ‘golden’ (first) hour after harvest led to an increase in the deterioration in fruit quality with increased weight loss, a rise in fruit respiration and an increase in disease incidence during shelf-life. It is anticipated that the ‘Coolberry rig’—an in-field chiller—could help growers manage their cool-chain logistics by ensuring fruits are cooled as quickly as possible. This could be extended to other perishable produce beyond strawberries.

Cutting down losses in the camel milk value chain

Besides fresh fruit and vegetables, products such as milk can also deteriorate rapidly leading to high loss and/or waste along the value chain. We collaborated with Egerton University and Anolie Women Camel Milk Cooperative in Isiolo County, Eastern Kenya to understand the challenges and to identify opportunities to reduce losses in the camel milk value chain from Isiolo to Nairobi. Loss reduction was achieved by introducing improved postharvest handling practices and the utilization of a cool chain system, alongside upgraded milk storage and transportation cans. These practical measures have not only minimized losses but have also ensured the delivery of high-quality fresh camel milk to consumers in Nairobi. This partnership has proven to be instrumental in benefiting both producers and consumers while bolstering the camel milk industry.

Food Loss and Waste valorisation

In Upton Sinclair's novel ‘The Jungle,’ the Chicago meatpacking industry used every part of the pig for profit. This is still the case in Southeast Asia, where pig by-products are transformed into food products. However, in East Africa, the market for these by-products is not well-developed, leading to environmental contamination and wasted resources. Through the Safe Food, Fair Food project, our Food Safety Systems expert, Prof. Delia Grace collaborated with Wambizzi Cooperative, the only authorized pig slaughterhouse in Kampala. They developed a modified biogas reactor to digest slaughterhouse waste efficiently. The biogas plant consists of three digesters that convert waste into methane gas which is used for heating water required by the slaughterhouse. The resulting effluent is being evaluated as organic fertilizer. Besides waste management, the plant also reduces firewood use and saves money.

Reducing Food Loss and Waste

For more information: